Lavorro Smart-Fab Virtual Assist Mitigation Workflow & Benefits

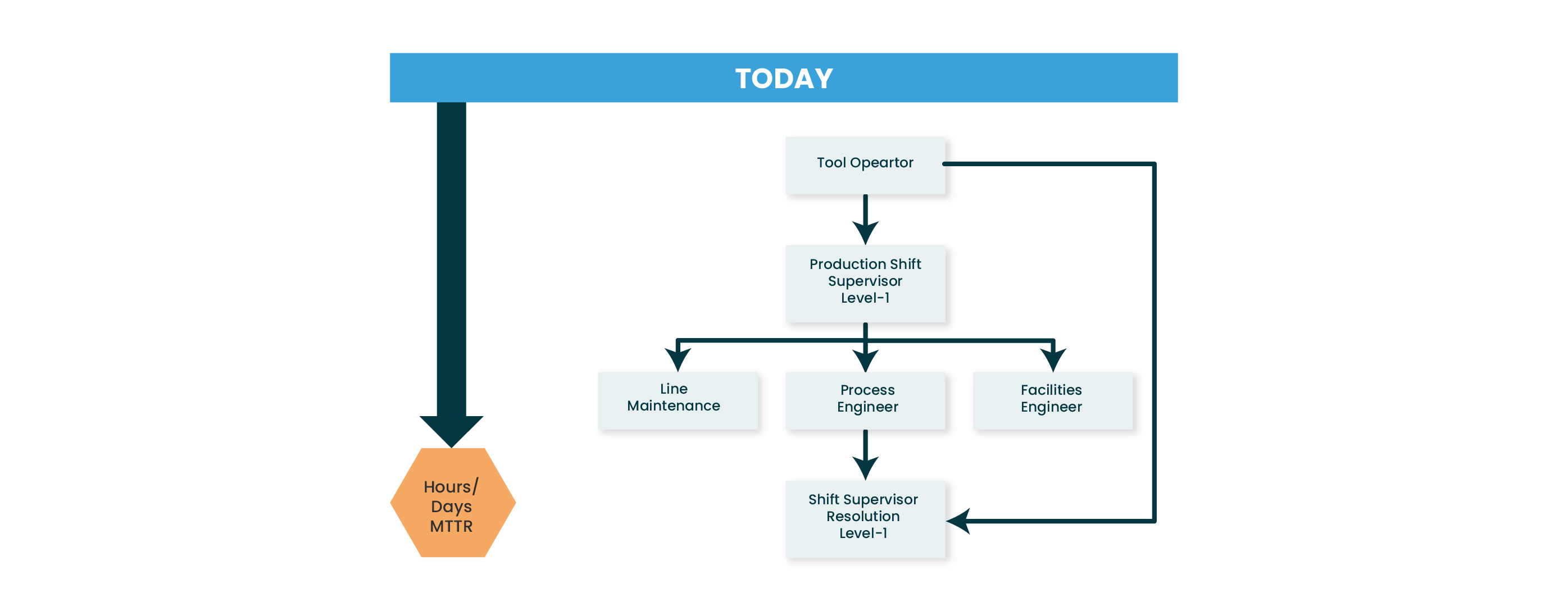

Fig shows: todays wafer fabrication work flow.

Level-1 Resolution: The tool operator today, when presented with any issue with a specific equipment production or operation issue immediately contacts the shift production supervisor. The supervisor reviews the problem and based on his assessment contacts the shift engineer either for line (equipment) maintenance, facilities or process engineering, also from the same shift. If they are able to resolve the issue, they provide heir solution to the supervisor and tool operator and the problem is hopefully mitigated. Depending on the problem this process may take hours or even a day to resolve. The key challenge is the immediate availability of information, equipment data analytics, and historical log of best-known methods (BKM).

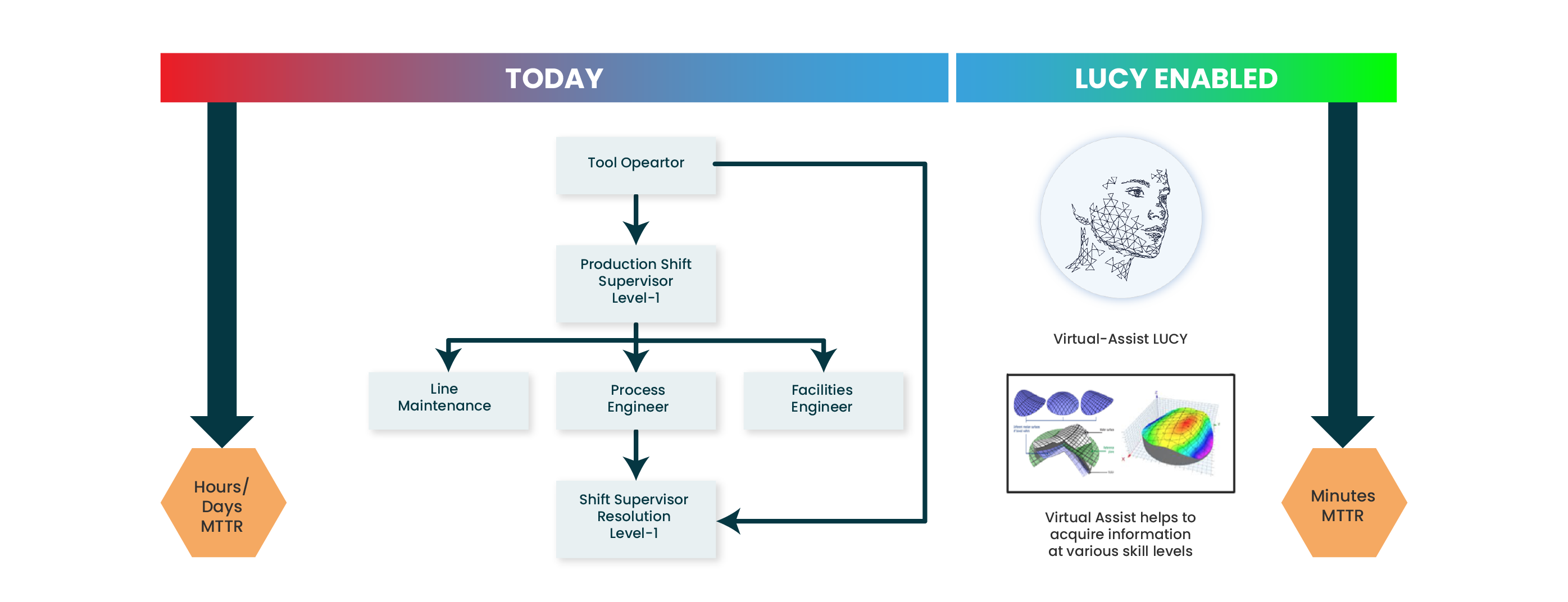

Fig shows: “Lucy” Virtual Assist enabled Level-1 Resolution.

Once the equipment is enabled with Lavorro’s Smart-Fab Analytics solution “Lucy” the equipment manuals, BKMs, Alarm data, equipment & facilities sensor data metrics and analytics information is readily available to the team. Lucy has the ability in most cases has the ability to even predict or suggest resolutions to the team. Depending on the qualification level of the local team this information can be reviewed at various skill level. This helps the problem resolution time to reduce to minutes, minimizing MTTR and maximizing productivity.

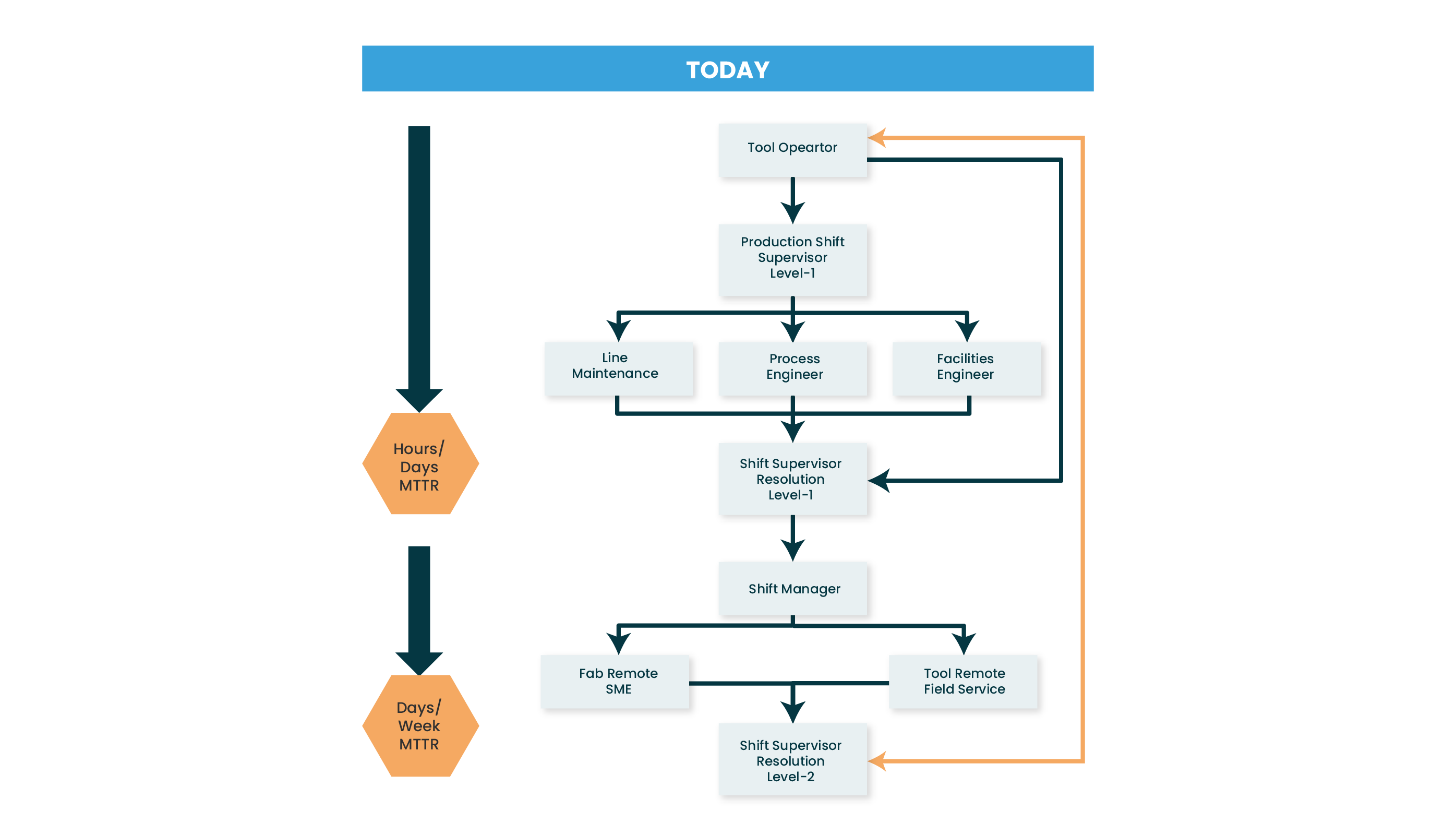

Fig shows: today’s Level-2 problem resolution work flow.

Level-2 Resolution: If the problem cannot be resolved at Level-1 stage, then the shift supervisor or the responsible shift engineer escalated the problem to a subject matter expert (SME) in consultation with the manager. Most of the time these experts or the manager are remote and in various time zones. They are mostly accessible over telephone and do not have access to any tool data. In some cases, the equipment manufacturer field service has to be contacted. This can take days or weeks (depending on if travel is required). During this time the equipment is down and production is stalled.

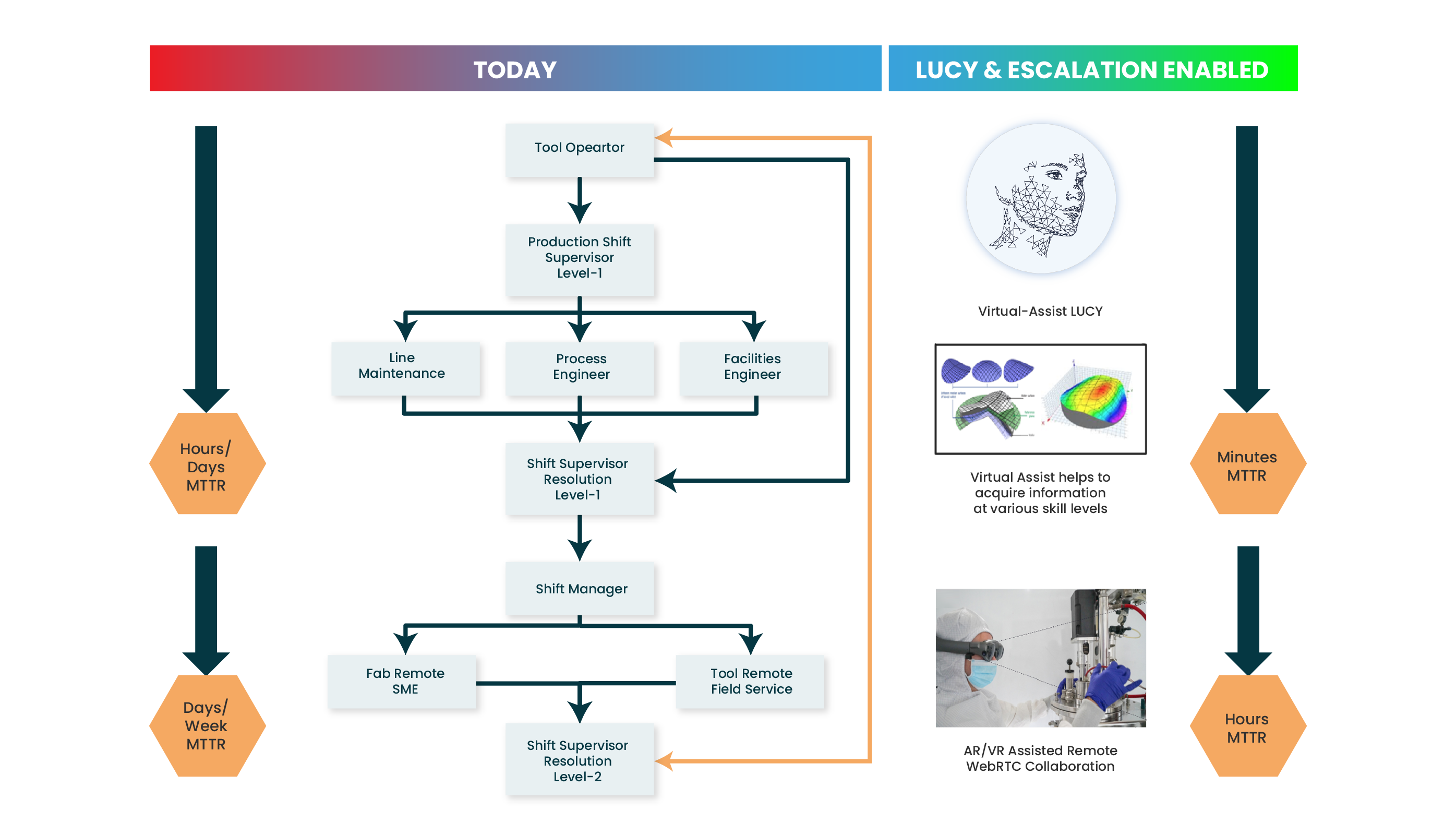

Fig shows: “Lucy” Virtual Assist enabled Level-1 & Level-2 resolution.

Once the equipment is enabled with Lavorro’s Smart-Fab Analytics solution “Lucy” which also included a build in escalation technology with AR/VR head gear, which operates on secure VoIP WEBRTC protocol, the authorized SME or Equipment field service personnel and interactively visualize as a group, if necessary, the equipment manuals, BKMs, Alarm data, equipment & facilities sensor data metrics and analytics information along with any predictive or suggested resolutions by Lucy. In addition, the SME has full access to the Smart-Fab SW dashboard to perform and additional query or analysis remotely, and suggest a resolution. This can be done in hours or minutes which drastically reduces the downtime, MTTR.